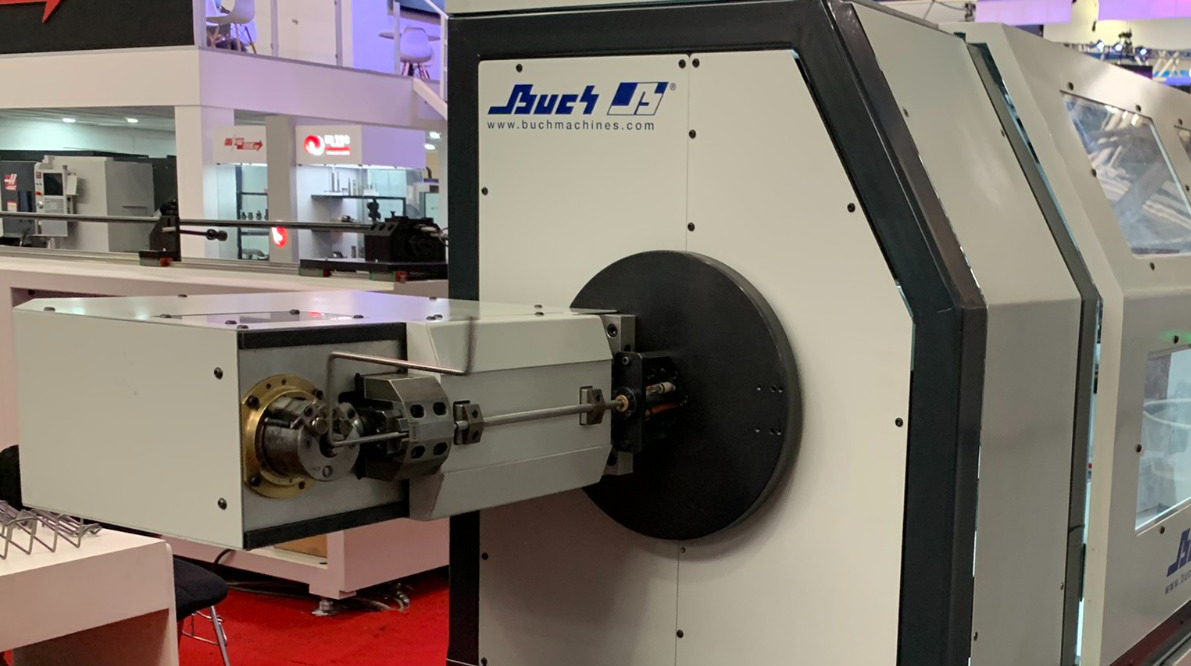

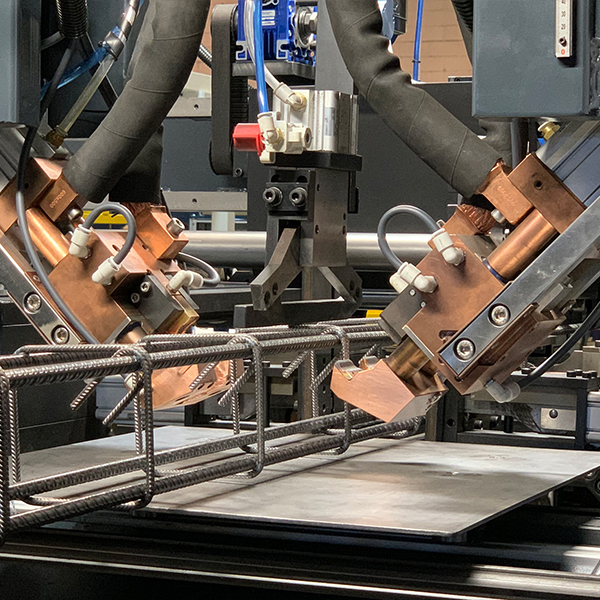

BML-series

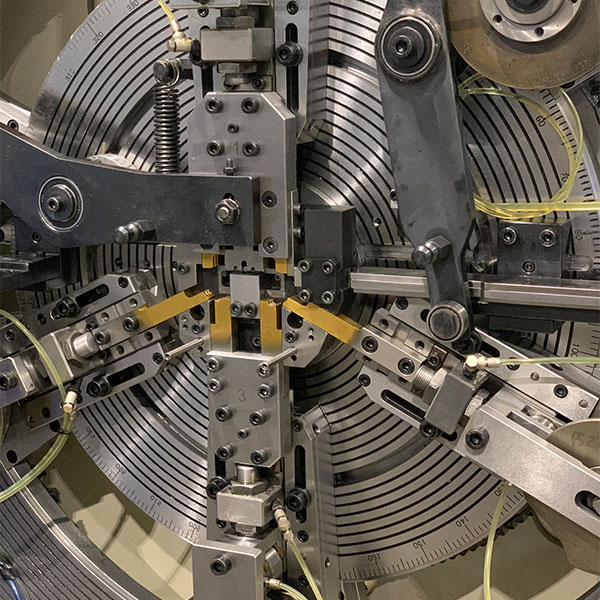

The BUCH BML series is ideal for producing, without the need for special tools, a wide variety of parts with numerous bends, whether symmetrical or asymmetrical, starting from coiled wire.

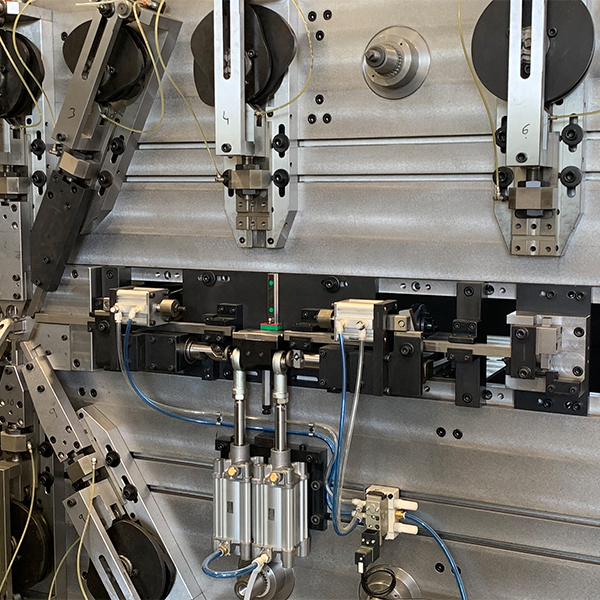

BUCH, has achieved a simple programming that allows us to be able to make changes to the parts quickly and safely.

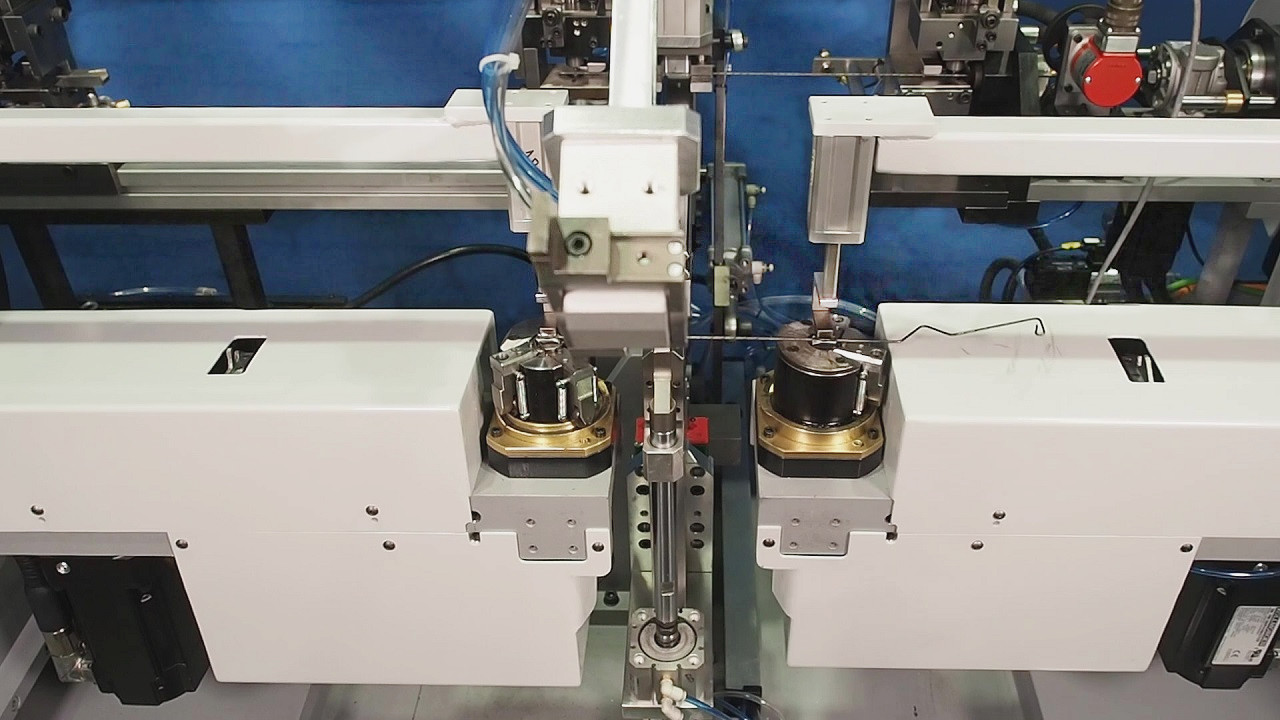

During the forming of the piece, we turn the heads, the wire is always static to achieve a higher quality final product.

BUCH has developed a CADCAM system that allows us to generate the program for the part that we have to manufacture from its drawing.

The machines allow to manufacture piece by piece or sets of several different pieces.