DCME-series

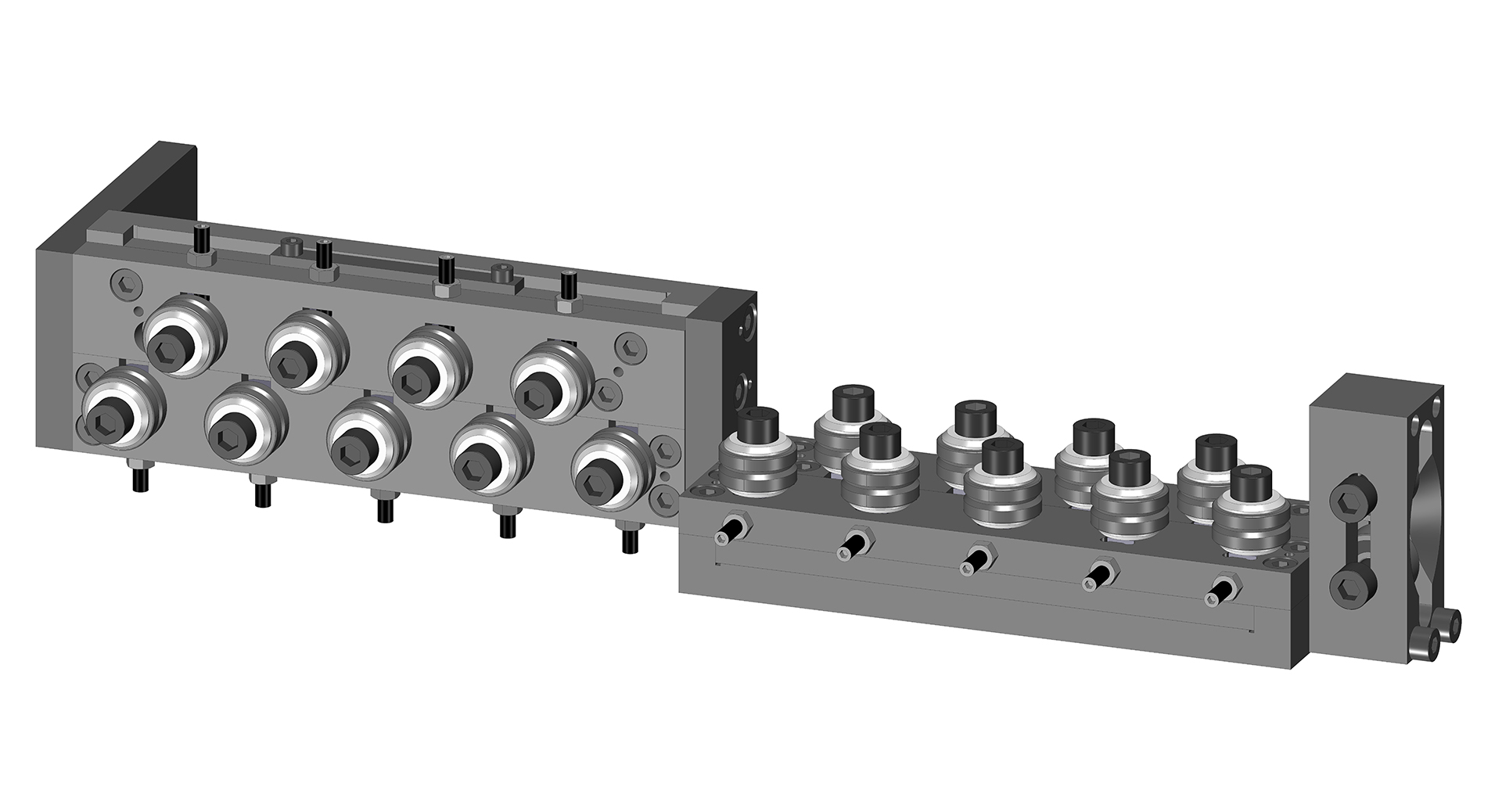

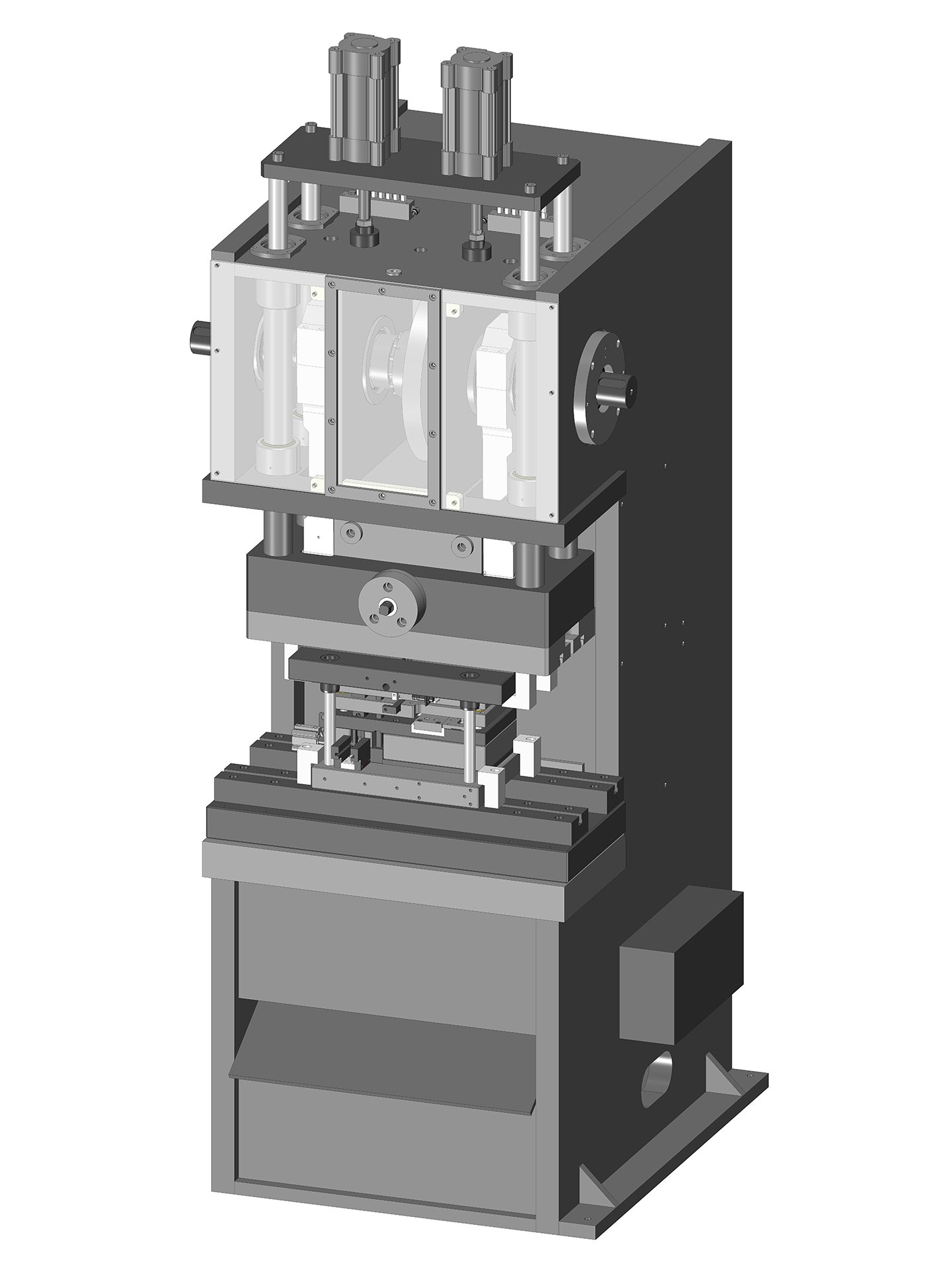

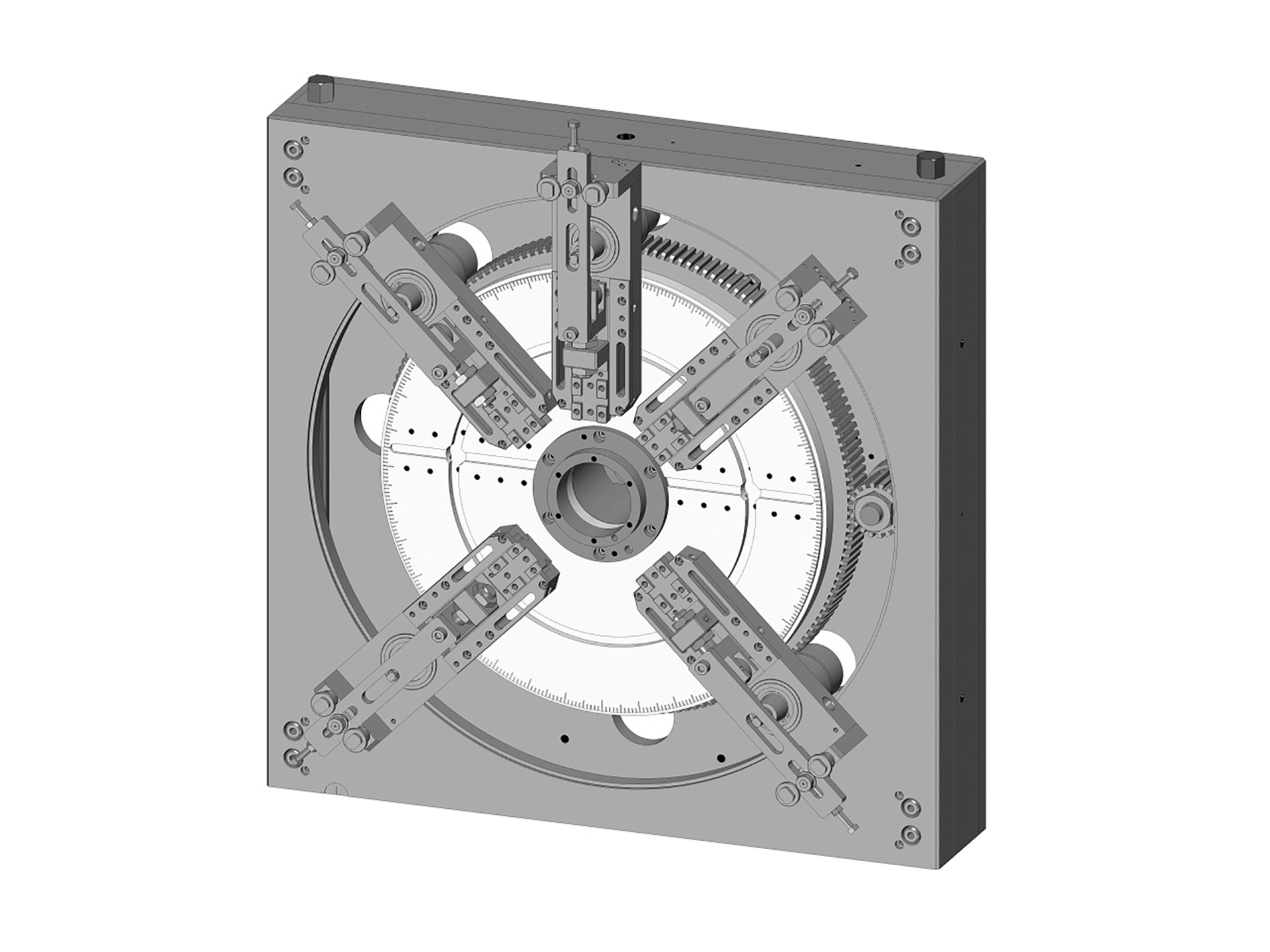

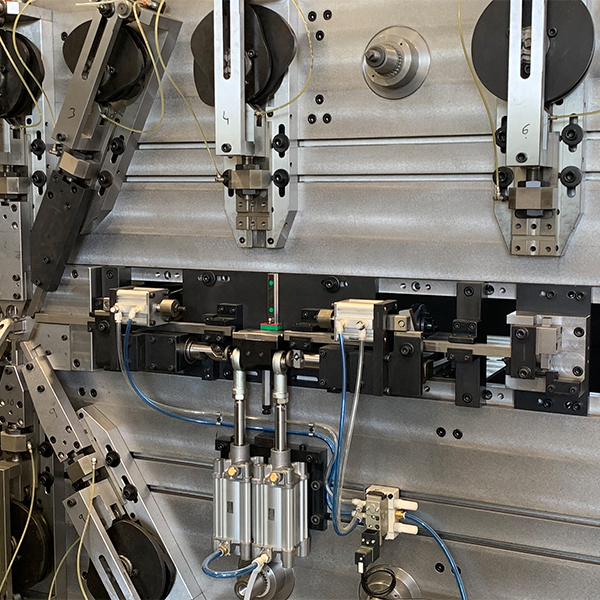

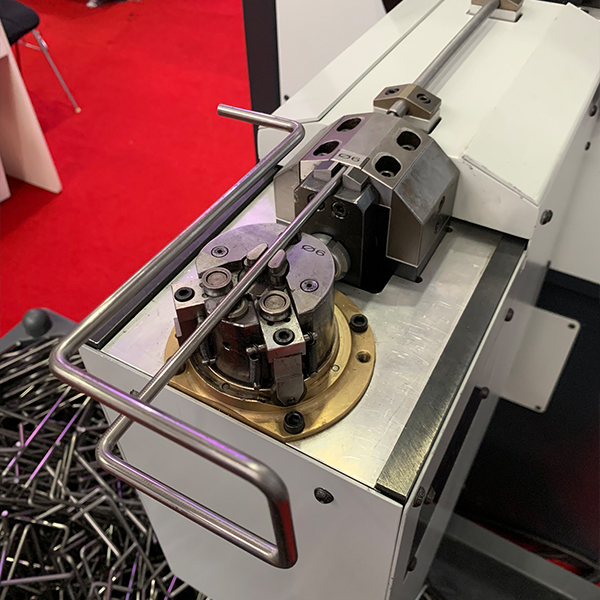

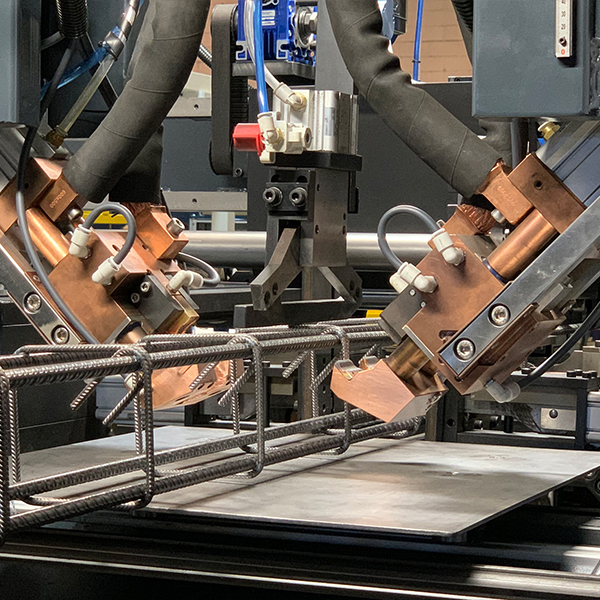

The DCME machines (Multi slide Electric Bending Machine) are universal type automatic machines designed by BUCH® for the production, in large series, of precision shaped parts made from roll materials, be they strap or wire. DCME machines combine precision, robustness and power, along with mechanical simplicity, absence of maintenance, and facilities in the design and adjustment of their tools. The modular design of this machine and the variety of existing modules allow a machine to be supplied with the specific characteristics requested by the customer. In addition to stamping and making difficult bends, the machines in this series allow us to perform multiple complementary operations such as: threading, chamfering, welding, assembling, etc. Reducing additional processes, which, on so many occasions, make the product more expensive.

Currently, the mechanics have been simplified and an independent servomotor has been incorporated in the bending unit, in the feeding, in the stamping and in the extraction of the already shaped product. These servomotors simplify machine maintenance and allow faster tool changes and independence between the different modules that make up the machine.