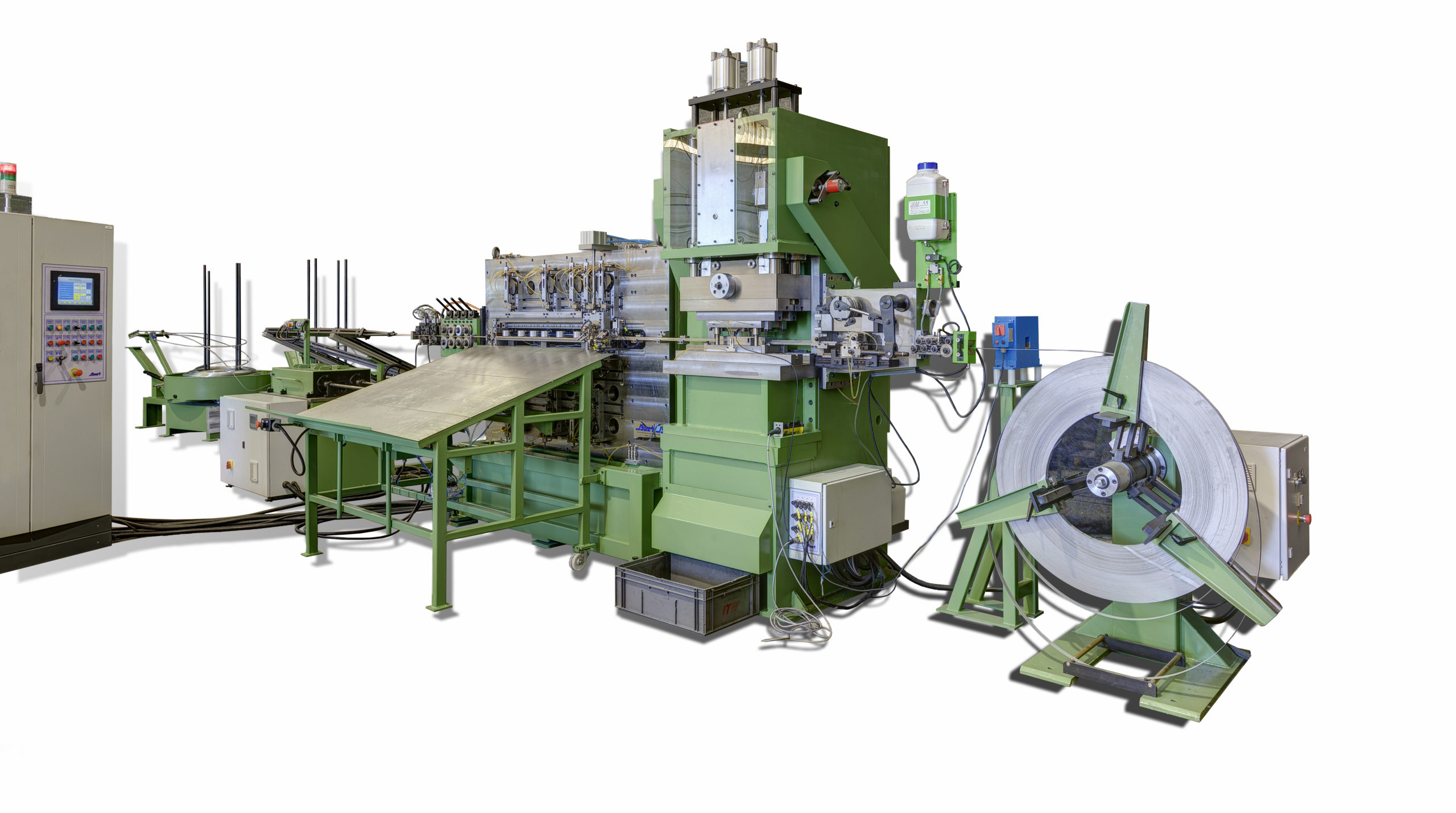

DML-series

The DML series machines share many characteristics with the DCME series. The main difference between one and the other is that they are of linear construction.

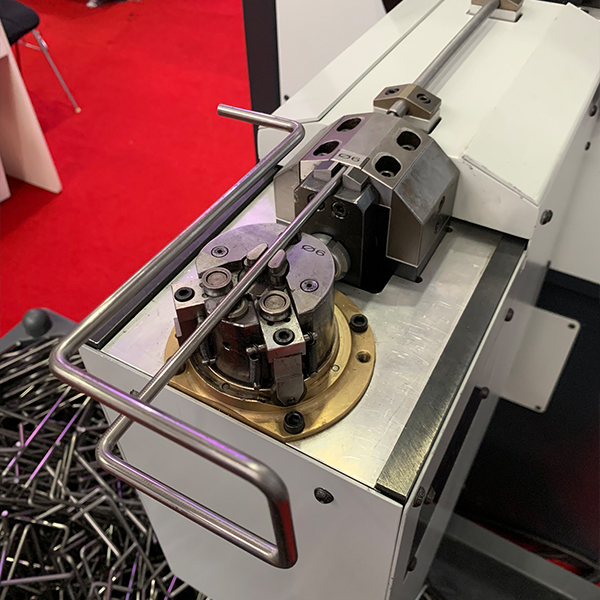

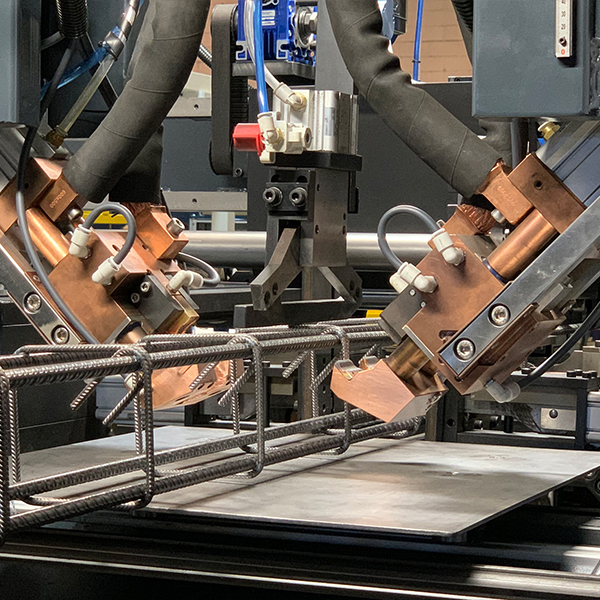

Like the DCME series machines, they are modular machines to which we can incorporate straightening, feeding, press modules… they also share the tool-carrying carriages, tappers, motion take-offs, etc.

The DML series is designed to work with wire or strap, but always with large or medium developments.

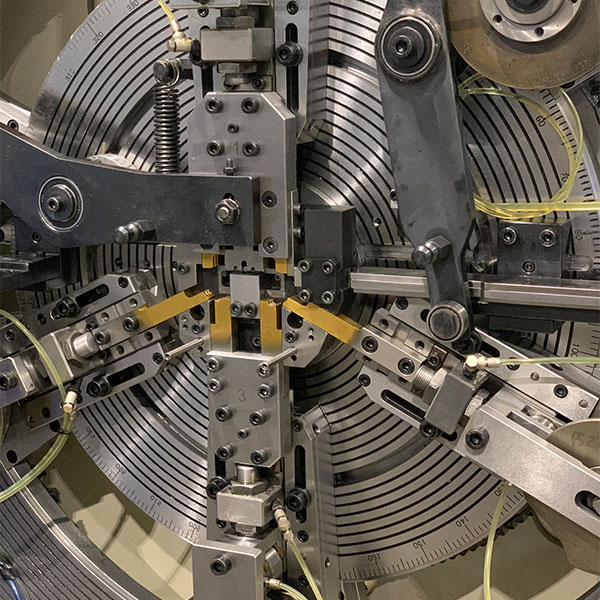

This model of machines has two work tables, located perpendicular to each other and both provided with fixing holes and slots that serve as support where to properly place the folding carriages, molds or any other element that we may need for the conformation of the pieces.

On the vertical table we have three lines of holes to be able to position the folding carriages depending on the height of the pieces to be manufactured and a central window where the work plate is fixed. It is starting from the lower face of this window, and perpendicular to it, where we find the horizontal table.

The drive of the DML bending machines is by means of easily programmable servomotors and with perfect synchronism between the different modules, or that guarantees optimal work.