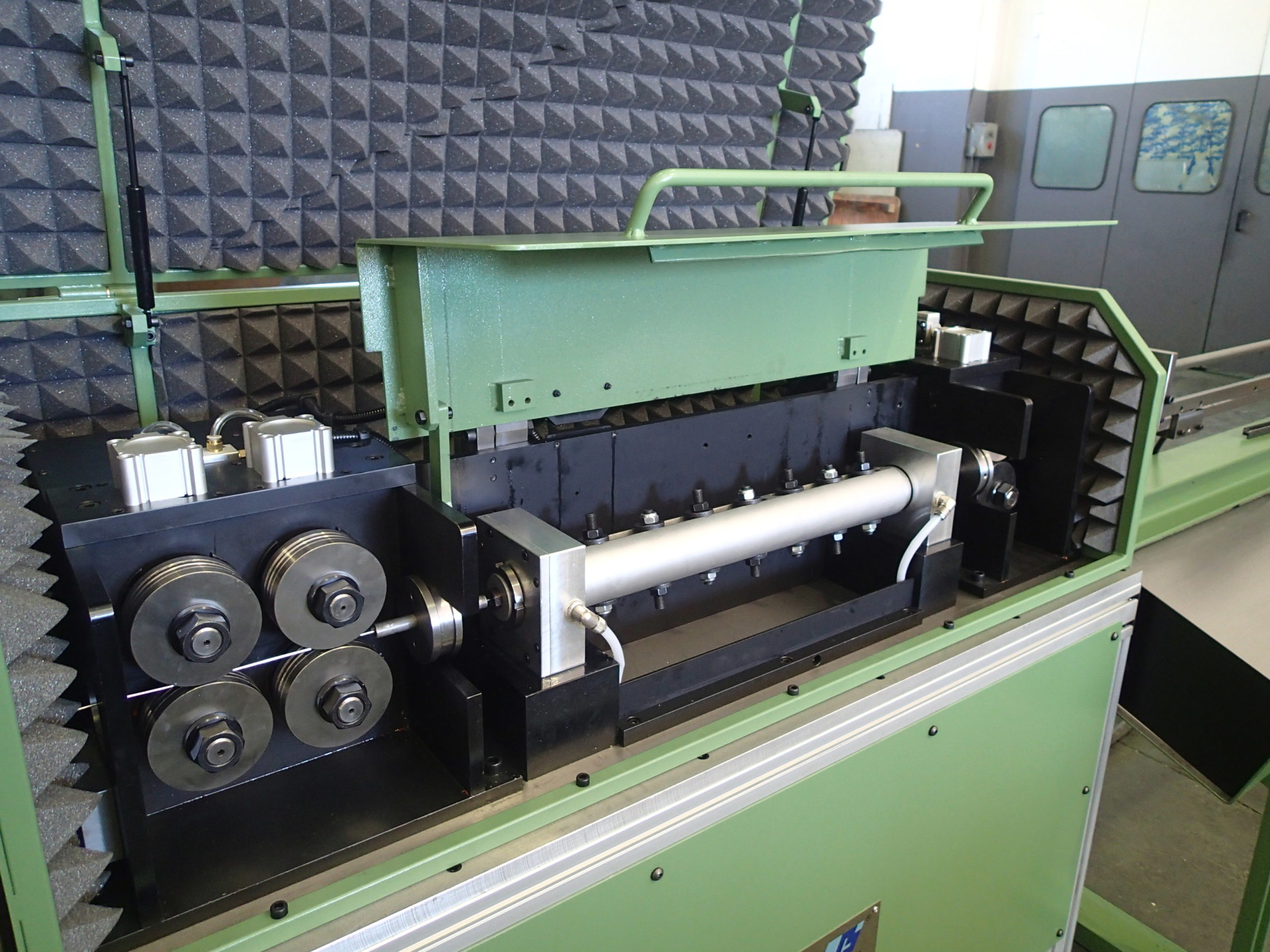

Straightening and cutting machines “WSC”

The BUCH model “WSC” wire straightening and cutting machines are high-speed machines, up to 120m/min., with which you can straighten and cut wire between Ø1mm. and Ø16mm. Its compact structure and four well-defined modules.

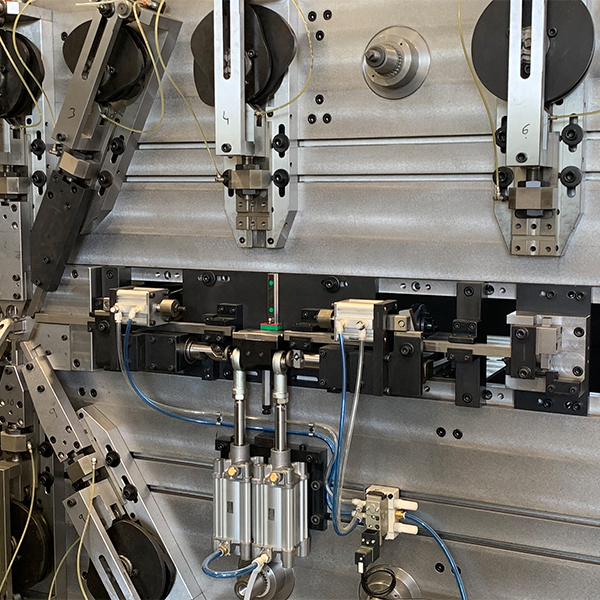

The first of the modules is the dragging of the material, which is done by means of treated and rectified steel rollers. We will have several sets of rollers depending on the characteristics of the wire that we have to straighten.

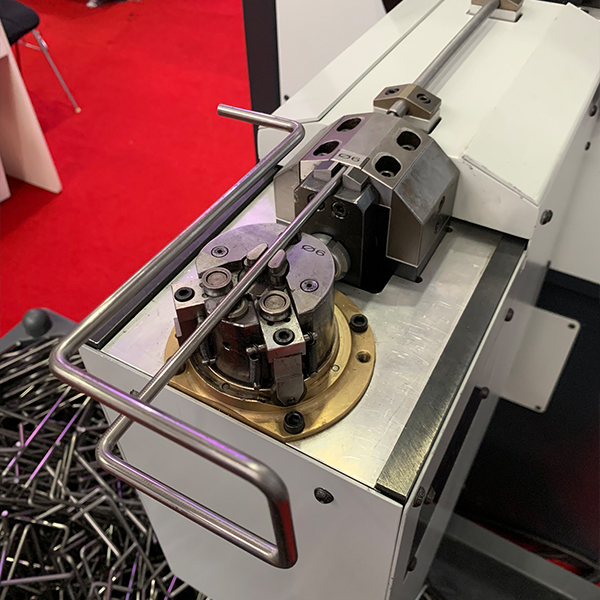

The second module is the straightening. To straighten we have a rotary straightener with dies or hyperbolic rollers depending on the material with which we work.

To regulate the straightening, the machine has a button that will allow us to quickly and precisely regulate the position of the straightening dice.

The drive of the straightener is by means of a motor with a frequency inverter.

By having independent electric motorization for the feed and straightening systems, we can achieve an optimal feed/straighten ratio depending on the hardness, diameter and composition of the material.

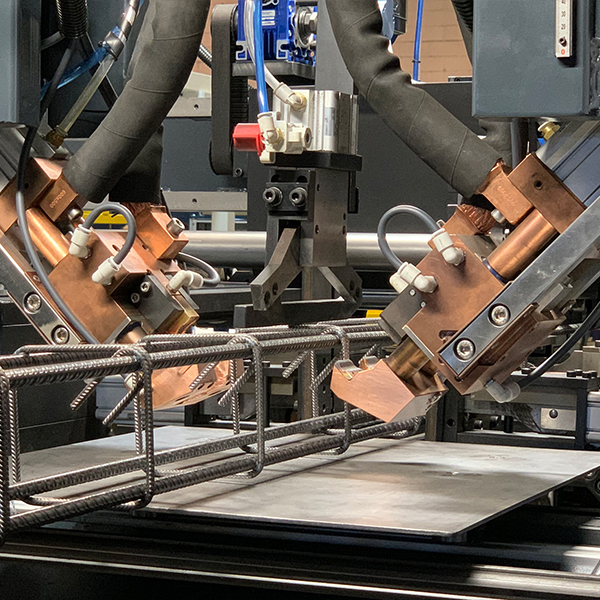

The third module is the cutting of the material. The cut is activated by a servomotor and consists of a nozzle and a shear that practically does not interrupt the advance of the wire. The servomotor allows us to place the blade at rest very close to the wire, as it advances we are going to cut the material and thanks to its design it allows us to feed while the blade goes back to start the cutting maneuver again.

Finally, the fourth and last module would be the extraction of the already cut material, which offers us several possibilities depending on whether we want to obtain the rods separately, or whether we have to carry out any other operation (beveling, blunting…).