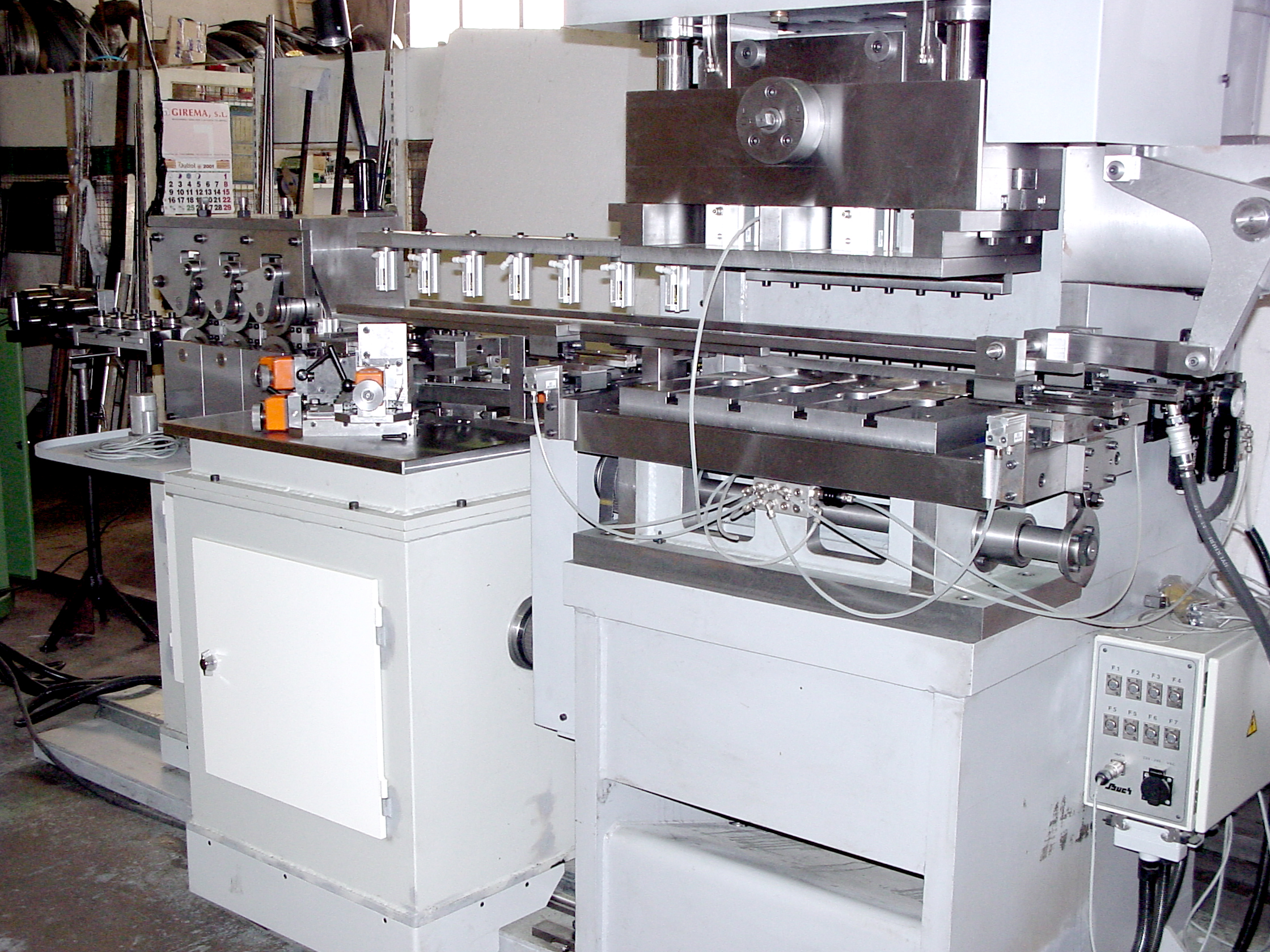

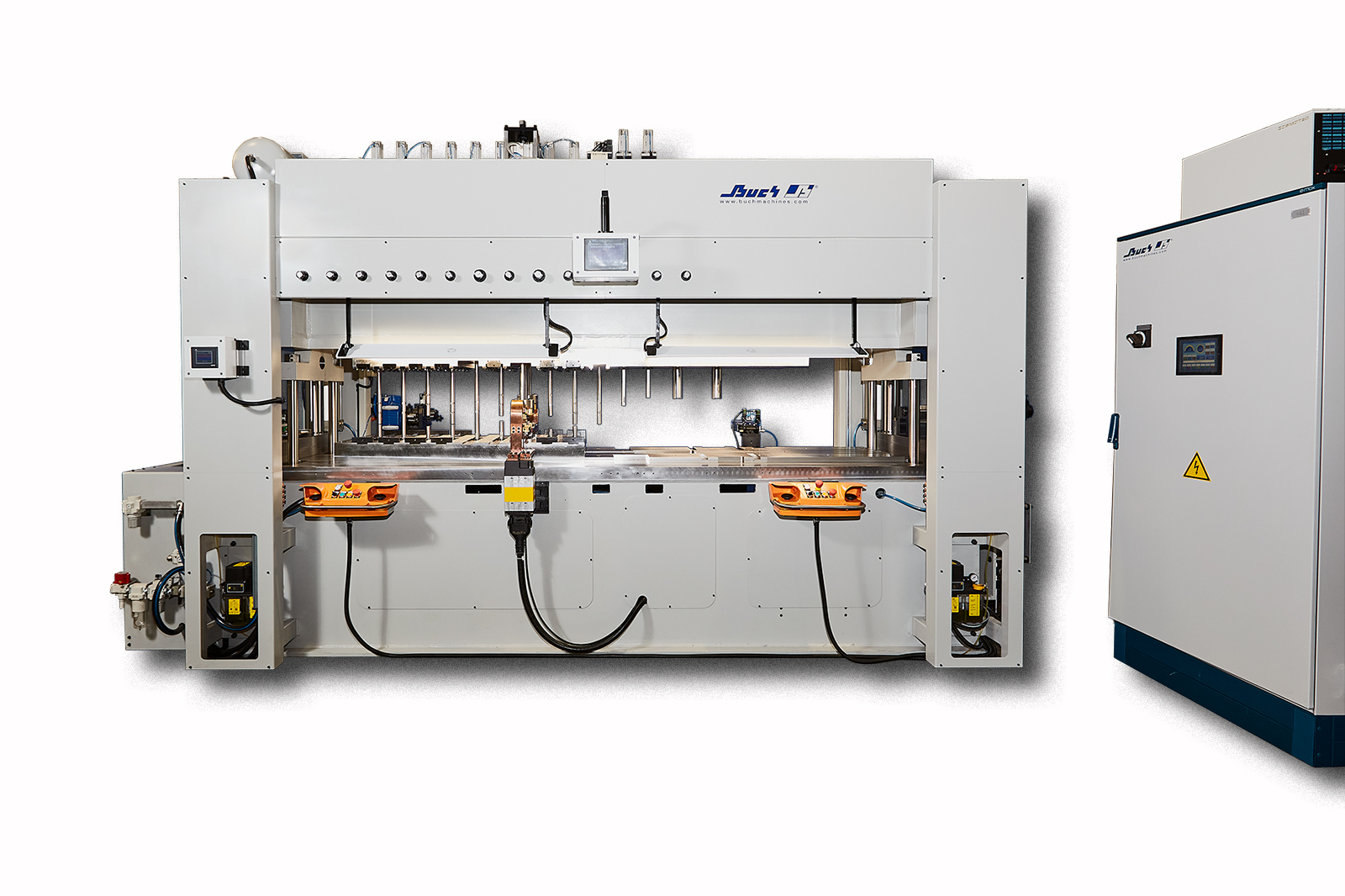

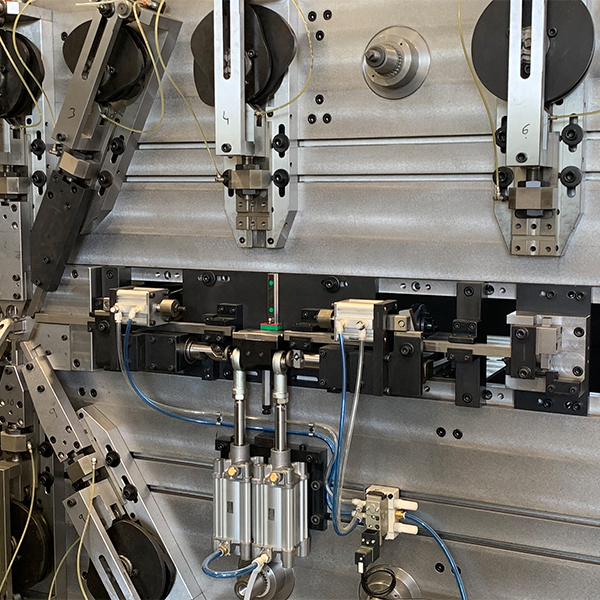

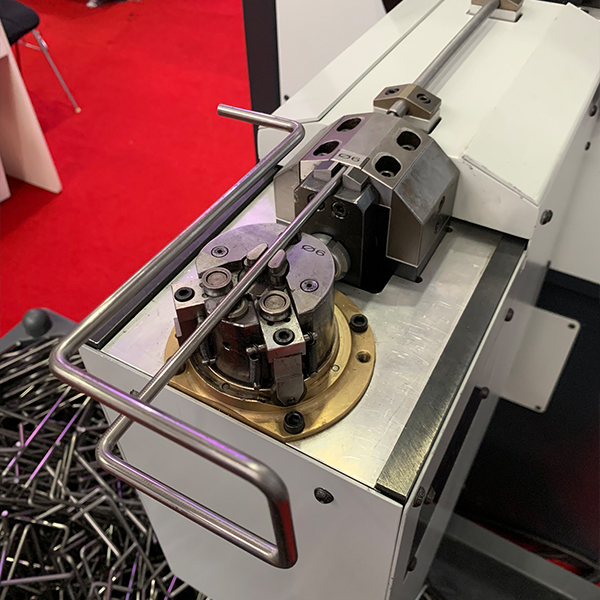

Mechanical presses are the best known and used system for stamping. BUCH® has developed its own presses that are often complemented by other equipment offered by the company. This experience has allowed BUCH® to be able to offer this element incorporated together with other equipment or individually.

Basically, we can define 2 types of press, the monobloc construction gooseneck mechanical presses and the transfer presses.